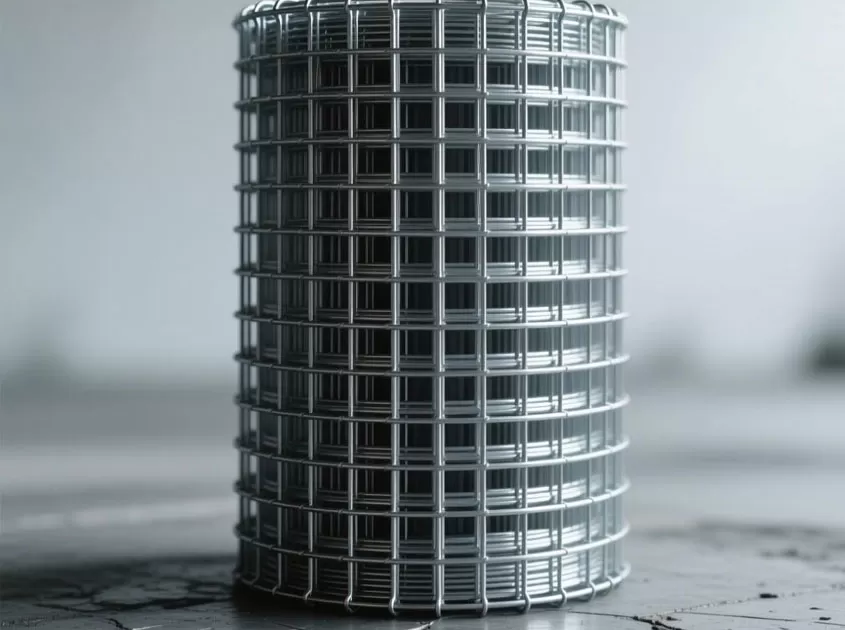

Holland Wire Mesh: Industrial use and effect display

Holland Wire Mesh, as an excellent industrial material, has demonstrated excellent results in various industrial applications. Its unique design and high customizability make it the solution of choice in the industrial sector. This article will delve into the extensive application cases of Holland Wire Mesh in industrial applications, demonstrating its outstanding performance in improving production efficiency, ensuring work safety and improving product quality.

Industrial Filtration and Screening

Holland Wire Mesh plays an important role in industrial filtration and screening. Its finely woven construction and optional stainless steel make it an excellent screen and filter media. In chemical, food, pharmaceutical and other industries, Holland Wire Mesh is often used to separate solid particles, liquids and gases, so as to achieve precise production process and product purity control.

Mechanical Equipment Protection

Mechanical equipment in industrial production often faces the risk of erosion and damage from particulate matter. Holland Wire Mesh is widely used in the protection of mechanical equipment, such as fans, pumps, conveyor belts, etc. By adding Holland Wire Mesh coverings in critical locations, debris and particles can be prevented from entering the machinery, extending equipment life while reducing maintenance costs.

Holland Wire Mesh has shown diverse and multifunctional application cases in the industrial field. Holland Wire Mesh plays a key role in areas ranging from industrial filtration and screening, machinery and equipment protection, metalworking and welding support, to industrial storage and transportation, and safety barriers and fencing. Its excellent performance and flexible design bring efficient, safe and reliable solutions to industrial production. With the continuous advancement of technology, the application prospects of Holland Wire Mesh in industrial applications will continue to expand, bringing more innovation and development opportunities to various industrial fields.

-

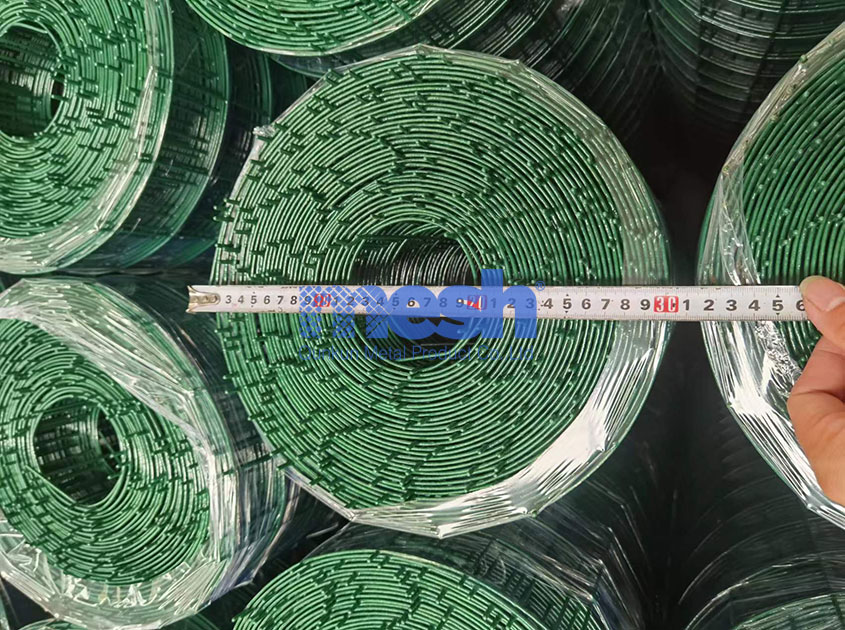

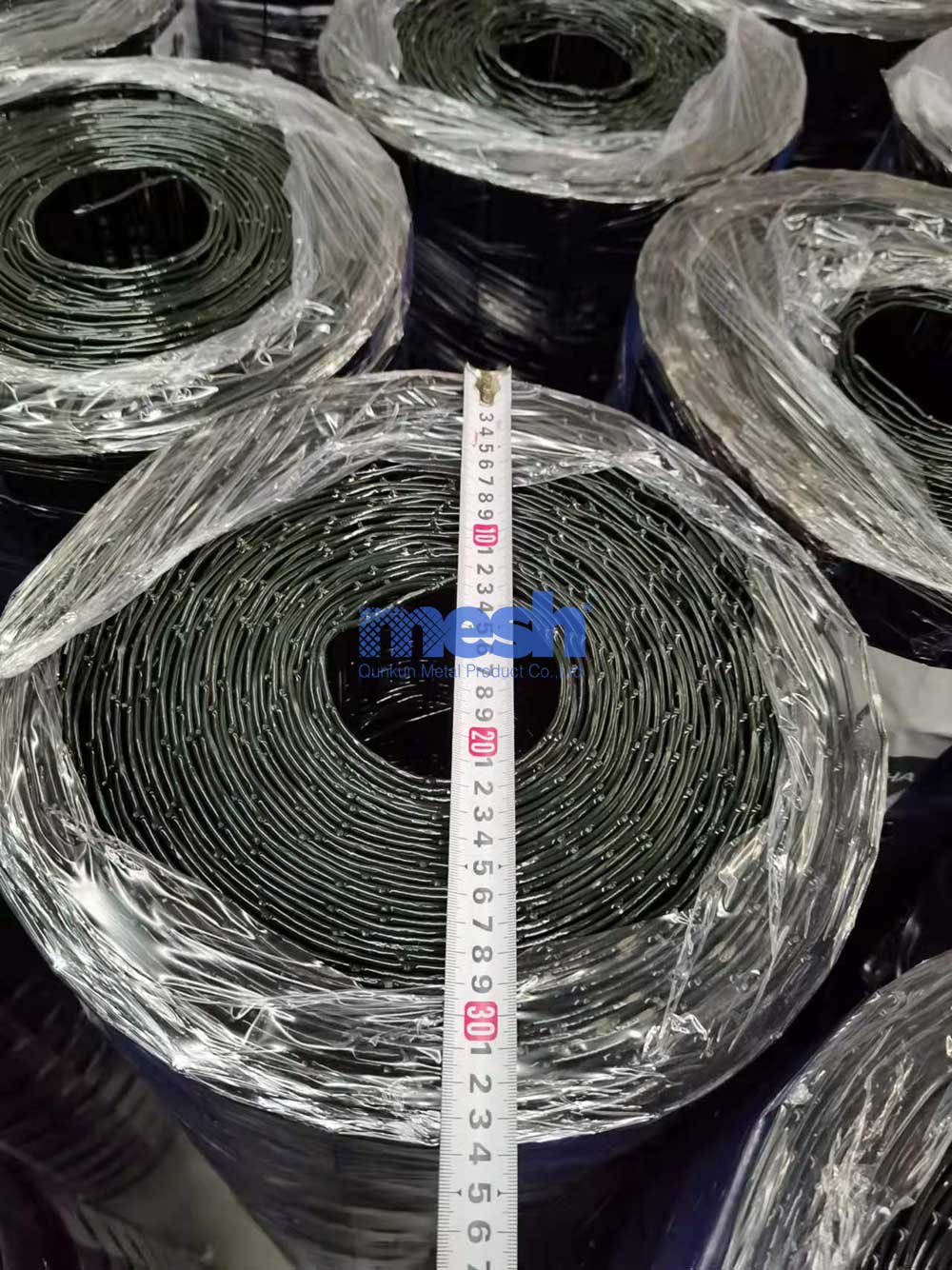

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China